Dream Chaser® Spaceplane Team Performs Successful Wind Tunnel Testing

October 08, 2020

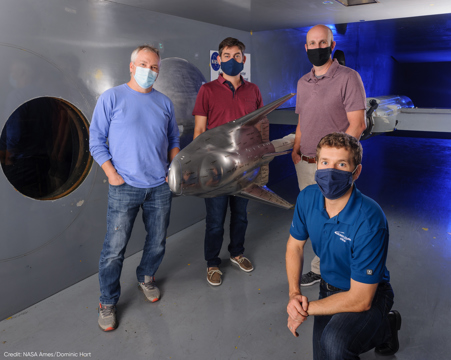

SNC recently completed a successful series of wind tunnel tests performed at NASA’s Ames Research Center over the course of three weeks, requiring both on-site and additional remote support, for more than 16 hours a day. It was a test our Dream Chaser® spaceplane team worked on for more than a year with preparation and planning.

Aerospace engineer, Mike J., was one of those on-site supporting the testing. He says, the testing isn’t a common one in the industry because of the specialized instrumentation used, but crucial to preparing for Dream Chaser missions.

“Unsteady forces, like vibrations, could produce a critical amount of force on the Dream Chaser airframe. That excessive force could result in failure of the structure. It’s important our engineers know all the forces acting on the airframe with as much accuracy as possible to design the structures with sufficient strength for safe flight operations.”

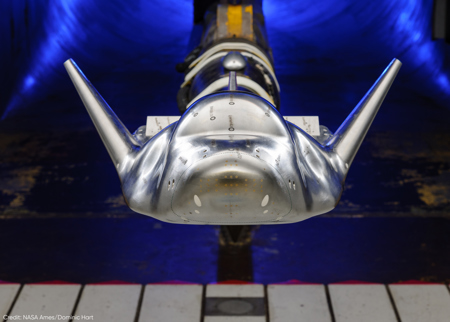

The Dream Chaser model used in the testing looks a little different from what we’re used to seeing in renderings. First up, it’s small; 1/10 the size of the actual vehicle. Mike says the size was determined based on what would allow for safe operations inside the wind tunnel space. It’s also silver! Of course, there’s a reason for that too!

“Typically, wind tunnel models are made of stainless steel or aluminum. Dream Chaser gets its color from the black and white Thermal Protection System (TPS) tiles,” Mike said. “While the test model incorporates the presence of TPS tiles, color isn’t relevant to wind tunnel testing.”

There are a few other details that also stand out on the model that are different from the actual Dream Chaser, like the text. The words written on the model identify a sensor and help the engineers associate it with the proper data channels. As for the white spots on the bottom of the model, it’s simply paste! It was used to cover items like the external fasteners and recessed bolt heads. That hardware doesn’t exist on the flight vehicle and the paste helps smooth the outer surface, much like the actual Dream Chaser.

After returning to SNC’s Louisville, Colorado production facility, we asked Mike what the best part of the trip was, and his answer was simple. “Having spent most of my career in wind tunnel testing, my favorite part is always successfully conducting the test. Our team performed seamlessly and the credit goes to everyone for making the test a success.”